“SPOTLIGHT solar fuels”: a disruptive photonic technology to create carbon neutral fuels

A new H2020 project that will develop innovative photonic devices for highly efficient, sunlight-fueled chemical processes.

The sun is a valuable source of energy. It can be used to produce electricity but it can also be stored into complex chemical molecules: the solar energy allows converting feedstocks such as carbon dioxide (CO2) and water into clean alternative fuels. These fuels are equivalent in terms of functionality to the fossil fuels, and thus they can be easily adopted by the current users, through the existing infrastructure. The great difference is that solar fuels provide reduction of greenhouse gas emissions (in particular CO2), which is larger than the reduction of biofuels.

Within SPOTLIGHT, universities, RTOs and companies join forces to develop a photonic device which facilitates efficient sunlight-powered conversion of CO2 and green H2 to the chemical fuel CH4 (Sabatier process) and to CO (reverse water gas shift process, rWGS) as starting material for production of the chemical fuel CH3OH.

Even if the technology for creating solar fuels is well known in the scientific community, there are still open challenges to bring it to industrial level, for large scale production. The key technical challenges to face are currently:

•Efficiency: the larger the fraction of sunlight that can be used to create chemicals, the less materials and feedstock would be necessary;

•Durability: materials degrade because of their exposure to sunlight and this has an impact on the efficiency and cost of the process;

•Costs: the costs of the process should be lowered as much as to make them comparable with the typical costs of fossil fuels;

•Industrial synergy: one of the key conditions to make the process sustainable is the industrial synergy between the solar fuel producers and industry that can provide feedstock (e.g. as by-products).

Accordingly, the current scenario of research on solar fuels mainly focuses on three macro themes: the chemical reactor, the solar optics and the catalysts.

In this context, the key objective of SPOTLIGHT is to develop and validate a photonic device and chemical process concept for the sunlight-powered conversion of the unwanted greenhouse gas CO2 and green H2 to the chemical fuel CH4, and to CO as starting material for production of the chemical fuel CH3OH. This will enable EU companies in the photonics and chemical industry to take the lead in creating a multi-billion industry involved in sunlight-powered chemical processes, and enables the EU to reduce its dependence on non-EU countries and regions for its energy supply.

SPOTLIGHT will guarantee a disruptive advancement on these themes, thanks to the development of:

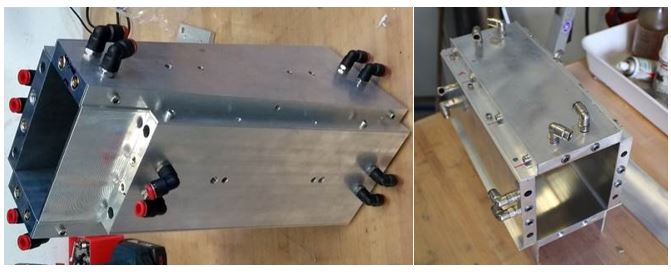

•A transparent flow reactor tailored for sunlight-powered Sabatier with gaseous starting materials and products, and packed-bed solid plasmonic catalysts capable of coping with p ≤ 20 bars and reactor T ≤ 250°C;

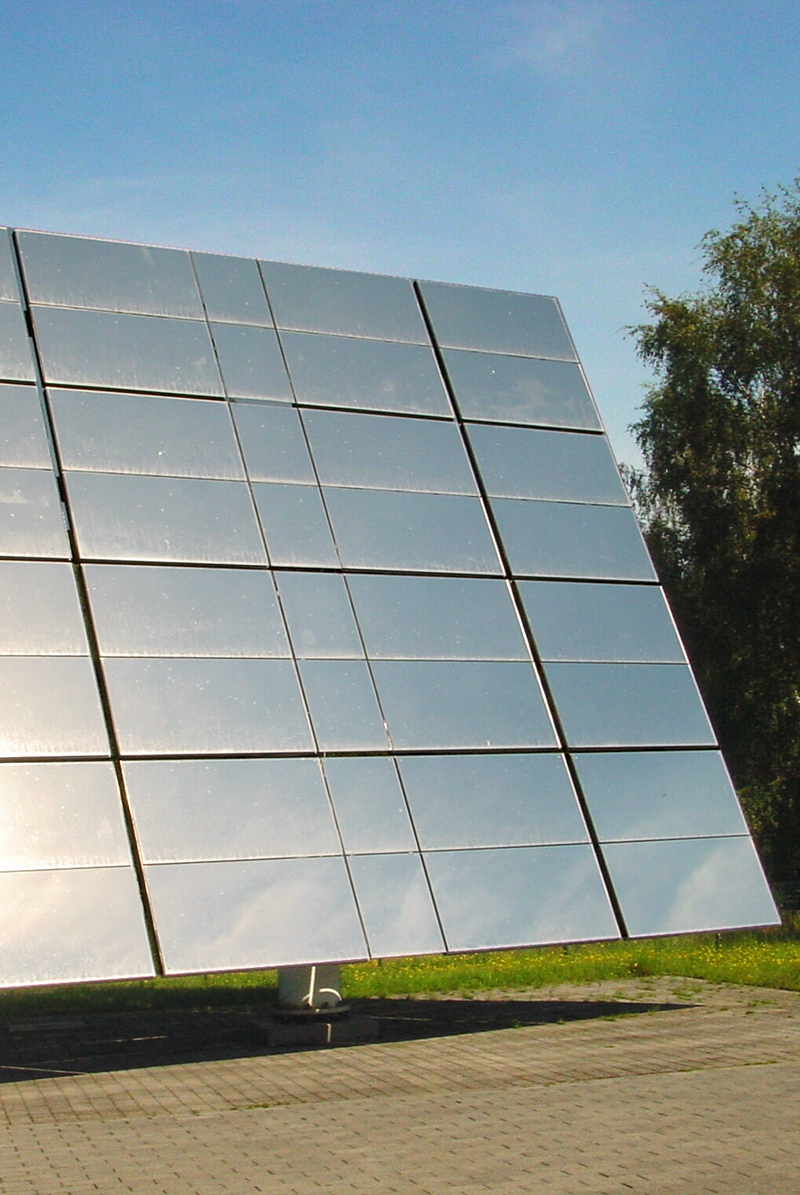

•Secondary solar optics for sunlight-powered chemical processes at solar concentration factor ≤ 20 and plate-shaped reactors.

•Energy efficient LED light source as solution to ensure continuous operation of sunlight-powered plasmon catalytic reactions;

•LED light source with tunable medium to high light intensity (between 1 and 20 kW·m-2) AND broad-spectrum emission (between 350 and 2500 nm) AND high electrical-to-radiation energy efficiency of ≥ 50%;

•Newly developed plasmonic nanocatalysts with tailored optical and catalytic properties and for high space-time-yield.

SPOTLIGHT’s new process for solar fuel production will be preliminarily tested in TNO’s facilities – the project coordinator – and then moved to DLR’facilities for extensive use and validation. More than this, a further study will be done, in order to verify the conditions for replicating the process in other environments and in synergy with different industrial contexts.